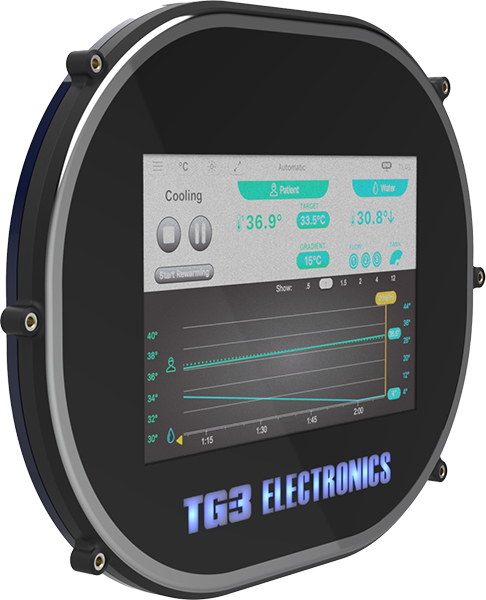

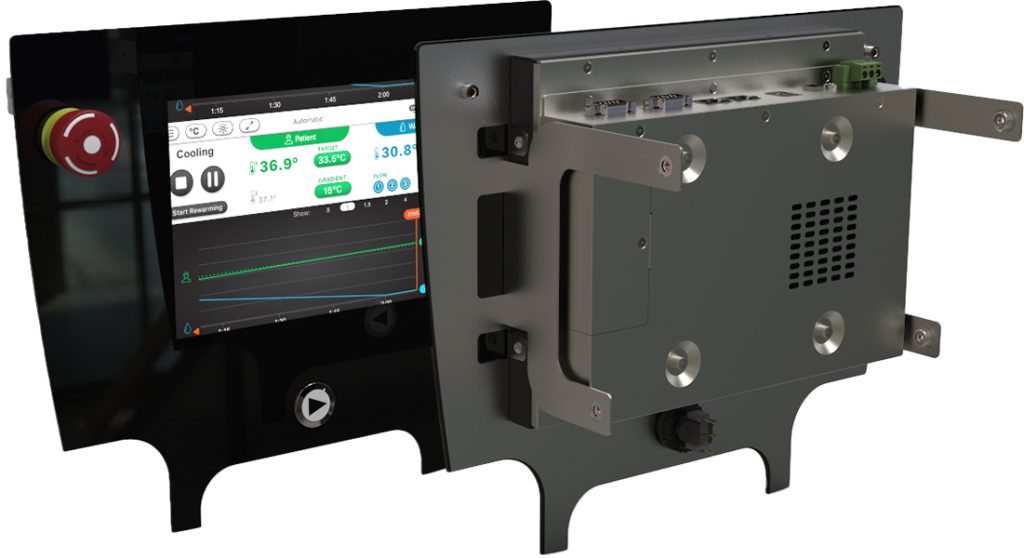

Most of TG3’s custom projects contain some form of touchscreen technology. TG3 is able to work with custom size and thickness on the displays. Some popular options for a custom display can include finished enhancements and custom touch tuning. Best of all, TG3 is able to offer such customized capabilities at the lowest cost possible to its customers.

PCAP

Projective Capacitive (PCAP) is performed on glass or plastic top surface solutions where patterned sensor elements are attached to the backside of the touch surface substrate. Once the surface is touched, signal levels on each pattern are measured. Touch is activated by bare finger, a thin-gloved hand, or a conductive stylus which is than detected by determining the relative levels of current between adjacent patterns.

Custom Touchscreens for Application

The engineering team works best with non-standard applications. Touchscreens with PCAP are built to last, especially when used for industrial or commercial applications. With a hard-coated surface, the screens can withstand the daily wear and tear of consistent interaction.

Adjustable Sensitivity

The best part of having a custom PCAP touchscreen is being able to control the sensitivity. Some touch controllers have adjustable parameters. For example, a customer can choose to have a higher sensitivity than normal so that the product works through thicker gloves, or a customer can prefer to have the product work faster in order to capture signatures. These are some of the parameters that can be adjusted for an optimal experience.

Custom Algorithms

TG3’s highly experienced engineering team has the capability to create algorithms in order to define the touch on PCAP touch technologies. PCAP screens have the ability to detect multiple touch points at the same time.

Test Equipment

TG3 has an expansive amount of resources to aid with testing PCAP products for validation. Most of TG3’s customers need help to define PCAP solutions. TG3 ensures each customer’s requirements are met.

Resistive

Resistive touchscreens are different than capacitive touchscreens in that a single touch on the screen compresses the flexible top layer into contact with the bottom glass layer. Resistive touchscreens have two thin layers with a thin gap in between the layers. The top layer is typically made up of clear material while the bottom layer is made up of rigid material. In contrast to PCAP touchscreens, resistive touchscreens can be activated by anything.

Types of Resistive Touchscreens

4-Wire Analog

In a 4-wire analog setup, both the top and bottom layers contain two electrodes. These electrodes are positioned perpendicular to one another. Electrodes on the top layer are the positive and negative Y axis, while electrodes on the bottom are the positive and negative X axis. The layer between both the glass and film improve the durability of the product to withstand various types of environments.

5-Wire Analog

A 5-wire analog setup consists of four electrodes placed at each corner of the bottom layer. There are four wires that connect these electrodes together. The fifth wire is the “sensing wire” embedded into the top layer. Because the top layer is working only as a pick-up layer, it can tolerate resistive changes without impacting the reliability of the touch points’ accuracy from the base layer. For this exact reason, the 5-wire is able to withstand temperature, humidity, and mechanical environments.

8-Wire Analog

The most sensitive resistive screen design is that of the 8-wire sensing circuit. The layout is similar to the 4-wire analog, but each of the bar electrodes contains two wires. This introduces some redundancy into the circuit because even if one of the wire pairs loses resistance over time, the second wire provides a secondary signal to the processor. For applications where accuracy is critical and recalibration is unacceptable, the 8-wire resistive touch screen is the preferred solution.

Electrical Interference Immunity

Electromagnetic Interference (EMI) is a measure of a device’s ability to operate as intended in an environment without disruption. PCAP is most susceptible to EMI while resistive is less susceptible. The TG3 engineering team has the ability to help advise the customer for the best solution that’s needed.

Force Sensors

Force sensors can be used in touch devices. At the core of force sensors are load cells which are transducers that convert force into measurable electrical outputs. TG3 utilizes force sensors in new technologies to triangulate location. This capability can solve additional shortcomings in other technologies.